|

|

|

|

| |

Machines for diamondes processing - for sales |

|

|

|

|

| |

Êàòåãîðèÿ: Business Catalogue |

Íîâîñòü îò: Admin | 16.01.2009, 11:37

(374-91)-77-85-24

Samvel Akopyan

Republic of Armenia Yerevan CJSC “Leader”

Machines for diamondes processing - for sales:

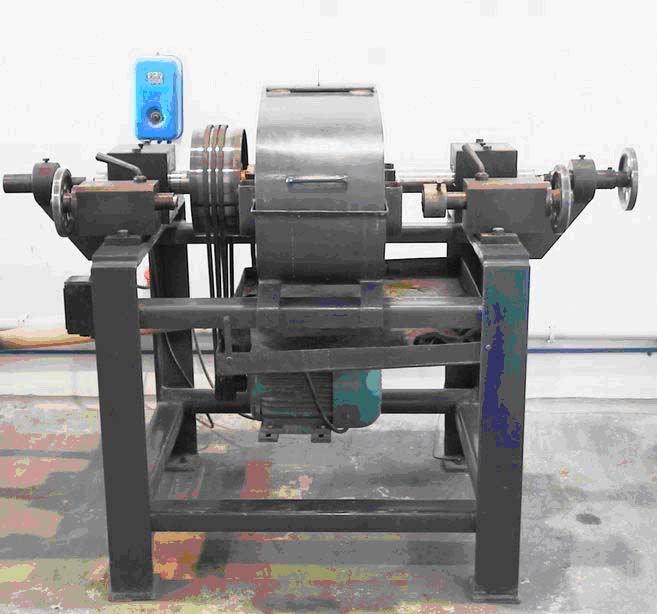

Machine for diamond cut MDK-2

Machine tool for sawing of diamond crystals SDC-2

Machine tool for grinding of cutting disks GCD-1

Machine tool for boring of the tenon (tongues) shaft of cutting disks BT-1

Machine tool for roughing (peeling) of diamond crystalls RDC-1

We accept orders for processing of diamonds

Machine for diamond cut MDK-2

Certificate

Type: grinding machine

Model: MDK-2

Manufacturer: CJSC “Leader”

1. Application, description and recommendation

Machine of the modek MDK-2 is applied for surface grinding, crystal diamond cutting with mass within 0.01-30carats in diamonds.

Machine is simple,reliable. It provides necessary conditions for obtaining of diamonds of the highest

(III Exellent) quality due to its new design of the lower poppet (tailstock) sleeze presenting droping of the cutting disk (plate) during operation.

Machine bed (frame)is made of steel pipes of rectangular section 100o100 mm with all-welded structure. The table is of steel plate with thickness of 20mm, faced by flexible PVC.

For desired precision and purity of treatment it is necessary to install the machine on foundation(reinforced concrete slab with thickness less than 160mm) far from machines operating impact load. Machine is levelled by 4 adjusting bolt on the bottom of the bed and fixed by 4 anchor collet bolts. Ccidental clearance between the bed basis and bottom is poured by liquid cement and sandy mortar with proportion 1/2: its hardening must occur during 7 days.

Electrical equipment of the machine is performed for connection to the three-phase alternating current network with voltage of 220/380 V. Necessary protection is provided.

Before the first starting it is requested to perform the following :

Thoroughly to clean the machine from contaminations; especially its poppet sleeze and cutting disk;

- To be conviced of the appropriate design of the machine level;

- To check reliability of the poppet sleeze fixation in any position;

- To be convinced og serviceability and normal functioning of all operating controls;

- To connect the machine to the serial grounding grid.

2. Specifications

1.Dimensions (length o width o height.)-

-1000x770x1360 mm.

2.Distance from the surface of the cutting disk to the

floor - 95mm.

3.Table dimensions (length o width) - 1000x770 mm.

4.Distance from the surface of the cutting disk to the top cross-piece – 385mm.

5.Diameter of the cutting disk aenea – 315mm.

6.Thickness of the cutting disk - 20mm (min 14ii).

7.Number of resolutions of the cutting disk –

-3000-3500 RPM

(due to the diametr of pulley of the electric motor)

8.Vertical shifting of the cutting disk – 50mm.

9.Laminaires – 2x36 W.

10.Cutting disk rotation drive electric motor:

type

power - 0,75 - 11 kW;

number of rotations – 1470 RPM

11.Weight of the machine – 260 kg.

12. Price

3. Warranty

Normal operation of the machine is ensured by “manufacturer”for a year when transportation , storage, installation and exploitation rules are kept. Warranty period ie valid from the date of the machine service but no later than 6 months from the date of its purchase. Machine is completed by 2 cutting disk.

Machine tool for sawing of diamond crystals SDC-2

Certificate

Type: sawing

Model: SDC-2

Manufacturer: CJSC “Leader”

Serial N:

Date of issue:

1. Purpose, description and recommendations

The machine tool of a model SDC-2is provided for sawing of natural diamonds crystals in weight from 0,04 up to 10 carats. The machine tool consist of the bed and 10 sawing heads installed on reiforced-cocrete table.

The bed is carried out from steel pipes of rectangular section 100o100 mm and 40o40mm of a folding design. Elecic motors are installed on regulating brackets(for tensioning of the flat inlimit belts) which are fixed on the bed by one for each head. Cantilever supports are also installed on the bed for two lamps.

Sawing head is presented as a frame with two ears (eyes)at back where the sawing lever carrying the diamond crystal in hinge mandrels, controlled load and limited support are bearings in two slots of the front frame. Spindel of the cutting disk is installed on bearing performing rotation from the plain belt drive.The machine tool is complterd by 10 spindels.

Before initial starting it is necessary to perform the following:

- carefully to clear the machine tool of pollution, paid special attention to clearing of the sawing heads:

- To be convinced of accuracy of the installation of the machine tool by level:

- To check the level of the belts tensionig;

- To be convinced of accuracy and normal operation of all controls:

- To connect the machine tool to a factory contour of grounding.

2. Specifications

1. Dimensions (length o width o height.) - m -1520x1000x1900 mm

2.Table size (length o width) -1520x1000 mm

3.Distance from the surface of a table up to a floor

-1200 mm

4.Number of resolutions of the sawing disk -up to 11000 RPM

5.Diameter of the sawing disks –60-90 mm

6.Number of the sawing heads -10

7.Laminaires – 2x36 W.

8.Electric motor of a drive of rotation of the sawing disk:

type

power - 120 W;

number of rotations – 2820 RPM

9.Weight 460 kg.

10.Price

3. Warranty

“Manufacturer” guarantees normal work of the machine tool within one year following the rules of transportations , storage, installations and operations. Warranty period is valid from the date of input of the machine tool in operation, but not later than 6 months from the date of purchase.

Machine tool for grinding of cutting disks GCD-1

Certificate

Type: grinded

Model: GCD-1

Manufacturer: CJSC “Leader”

Serial N:

Date of issue:

1. Purpose, description and recommendations

Machine tool GCD-1 is provided for grinding of the working area of iron cutting disks, machines for cutting of diamond crystalls of diameter 300/320mm.

The machine tool consists of the bed made of steel angles 100x100mm of all-welded design, spindle(on two self-labricated supports-stocks) with grinding disk.(Located in bunker of the steel plate), left and right controlling stocks for fixation, feeding of the cutting disk and cantilever for electric motor drive.

Spindle rotation is performed through cone-belt drive (three belts). Besides, the belts tension is provided by the weight of the electric motor. The machine tool should be installed on foundation (reinforced-concrete plate of the thickness not less than 160mm ) far from the machines working with shock loading.

The machine tool is fixed by 4 anchor(collet) bolts strictly in horizontal position by the level.

The electric equipment of the machine tool is executed for connection to a network of a three-phase alternating current by voltage 220/380V and necessary protection is provided.

Before initial starting it is necessary to perform the following:

- carefully to clear the machine tool of pollution, paid special attention to clearing the surface of the iron segments of the grinding disk;

- To be convinced of accuracy of the installation of the machine tool by level:

- To be convinced of accuracy and normal operation of all controls:

- To connect the machine tool to a factory contour of grounding.

- Be sure to close bunker door

2. Specifications

1. Dimensions (length x width x height.) - 1570x850x1150mm

2.Number of spindle rotations

3.Lateral shifting of the cutting disk

4.Electric motor of a drive of rotation of spindle :

type

power - 5,5 kW;

number of rotations –960 RPM

5.Weight 350 kg.

6.Price

3. Warranty

“Manufacturer” guarantees normal work of the machine tool within one year following the rules of transportations , storage, installations and operations. Warranty period is valid from the date of input of the machine tool in operation, but not later than 6 months from the date of purchse. The machine tool is completed by one indicator and flat belt.

Machine tool for boring of the tenon (tongues) shaft of cutting disks BT-1

Certificate

Type: boring

Model: BT-1

Manufacturer: CJSC “Leader”

Serial N:

Date of issue:

1. Purpose, description and recommendations

Machine tool of the model BT-1 is provided for boring of the shaft tongues of cutting disks.

The bed of the machine tool is made of the rolled angular steel 100o100 mm of all-welded design.

Two stocks are installed on horizontal area of the bed for rotation (from the left side) and supporting of the cutting disk, including also binary rest with electromotor. Rotation of the cutting disk is performed by cantilever fixed to the pully-whell on the left stock and cantilever catching connected to the shaft of the cutting disk.

But rotation of the pully-wheel is performed by electromotor through V-belt drive.

Binary rest is used for appropriate and smooth feed in direction of two cross axes of specially formed grinding disk on the shaft of electric motor.

For achievement of necessary accuracy and cleanliness of grinding (sharpeninig) it is necessary to install the machine tool on the foundation(reinforced-cocrete plate of the thickness not less than 160mm) far from the machines working with shock loading and to fix by 4 anchor bolts M10.The electric equipment of the machine tool is executed for connction to network of a three phase alternating current by voltage 220/380V and necessary protection is provided.

Before initial starting it is necessary to perform the following:

- carefully to clean the machine tool of pollution, paid special attention to cleaning stocks and rest;

- to be convinced accuracy of installation of the machine tool by level ;

- to be convinced of serviceability and normal work of all controls;

- to connect the machine tool to a factory contour of grounding;

- to install cutting disk on adjusting supports of the stocks effectively fixing by hand lever on the left side;

- to connect cantilever clamp to the shaft of the cutting disk;

- to lean the cantilever from the pulley wheel against cantilever clamp (for prevention of dynamic loads) by hand.

- To check the solidness of the grinding disk.

2. Specifications

1. Dimensions (length o width o height.) 1100x480x1200 mm

2.Distance from horizontal area up to the floor- 850 mm

3.Electric motor of a drive of rotation of the cutting disk type

power -

number of rotations -

4.electric motor grindstone (sharpener)

type -

power -

number of rotations -

5.Weight - 135kg

6.Price

3. Warranty

“Manufacturer” guarantees normal work of the machine tool within one year following the rules of transportation, storage, installation and operation.

Warranty period is valid from the date of input of the machine tool in operation but not later than 6 months from the date of purchase.

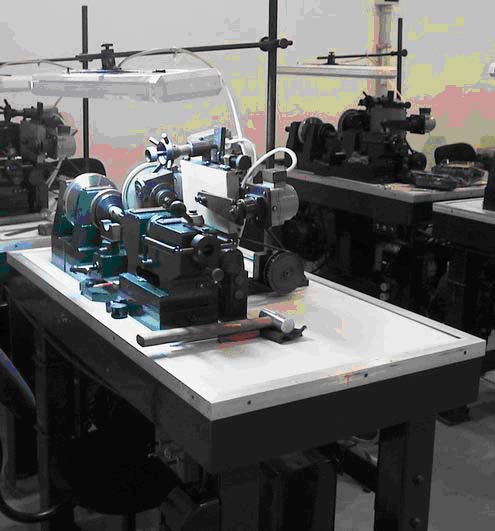

Machine tool for roughing (peeling) of diamond crystals RDC-1

Certificate

Type: peeling

Model: RDC-1

Manufacturer: CJSC “Leader”

Serial N:

Date of issue:

1. Purpose, description and recommendations

The machine tool of the model RDC-1 Is provided for peeling (roundings) of diamond crystalls in weght from 0.01 up to 30 carats.

The bed of the machine tool is made from steel pipes 80o80mm of a folding design. Table is reinforced-cocrete covered with plastic compound.

Peeling head consists of a bed with two stocks with spindles on sliding bronze bearings . Synchronous rotation of spindles of two stocks(heads ) is carried by transmission with two gear belts if transfer.

Diamond crystal is supported by two frames between two cartridges(floating and fixed).

Peeling-rounding-off of a crystall is performed manually by special device (accessory)”gun”equiped with the second crystall and (or) peeling device which is equiped with a disk of a diamond covering.

For achievement of necessary accuracy and cleanliness of processing the machine tool should be installed on a foundation(reinforced-concrete plate with thickness not less than 160mm) far from the machines oprating with shock loading.

The machine tool is fixed by 4 anchor collet bolts strictly in horizontal position.

The tool machine is equiped with electric motor of a direct current 2 PB having the electronic control panel allowing to choose a mode of operation according to processable crystalls of diamond. The electric equipment of the machine tool is performed for connection to a network of a three-phase alternating current by voltage 220/380 V and necessary protection is provided.

Before initial start it is necessary to perform the following:

- carefully to clear the machine tool of pollution, paid special attention to cleaning of the peeling head:

- to be convinced of accuracy of installation of the machine tool by level;

- to check up reliability of fixing of the floating head in any position;

- to be convinced of serviceability and normal work of all controls;

- to connect the machine tool to a factory contour of grounding.

2. Specifications

1. Dimensions (length o width o height.) -1150x600x1160 mm.

2.Distance from a surface of a table up to a floor - 900mm.

3.Table sizes -

4.Number of rotations of a spindle - 0-2800 RPM

5. Laminaires – 2x36 W.

6.Electic motor of a spindle rotation drive

type - 2PB

power - 0,75 kW;

number of rotations – 0-3000 RPM

7.Weght – 325 kg

8.Price -

3. Warranty

“Manufacturer” guarantees normal work of the machine tool within one year following the rules of transportation, storage, installation and operation.

Warranty period is valid from the date of input of the machine tool in operation but not later than 6 months from the date of purchase. The machine tool is completed with two frames.

|

|

|

|

|

|

|

|

| |

Ñ÷¸ò÷èê |

|

|

| |

| Ïí: |

136 |

| Âò: |

34 |

| Ñð: |

271 |

| ×ò: |

359 |

| Ïò: |

308 |

| Ñá: |

279 |

| Âñ: |

118 |

| Âñåãî: |

611856 |

| Ðåêîðä: |

1604 |

| OnLine: |

9 |

|

|

|

|